end suction pump meaning

As a buyer you will often find it difficult to choose among the multiple pump types that can be selected for the same application. The most common materials used are cast iron bronze and stainless steel.

Pump Suction Pipe Design Considerations

Many designs have a centre line discharge to comply with worldwide or regional standards.

. They are almost always single stage pumps meaning they have only one impeller. Cost effective and reliable they are suitable for a range of pumping applications. In this pump liquid enters in the impeller through one suction pipe only.

Should always be avoided. Less than 65 m hence the selected pump will work good. They are almost always single stage pumps that is they have only one impeller.

An End Suction Pump is a type of Centrifugal Pump where the suction is axial and the discharge is at 90 degrees to the suction. An ANSI pump is an end-suction pump that conforms to the dimensional envelope described in the ANSI pump standard. Manufacturers provide a range of materials of construction sizes and designs for applications involving water at ambient temperature abrasive slurries high pressure and high temperature.

It is generally used for pumping oil wells and viscous liquids applications. This manual covers the installation operation and maintenance of Patterson Pump end suction pumps. We offer the most comprehensive line of double suction end suction multistage and vertical turbine pumps for chemical feed water supply booster low lift and high lift.

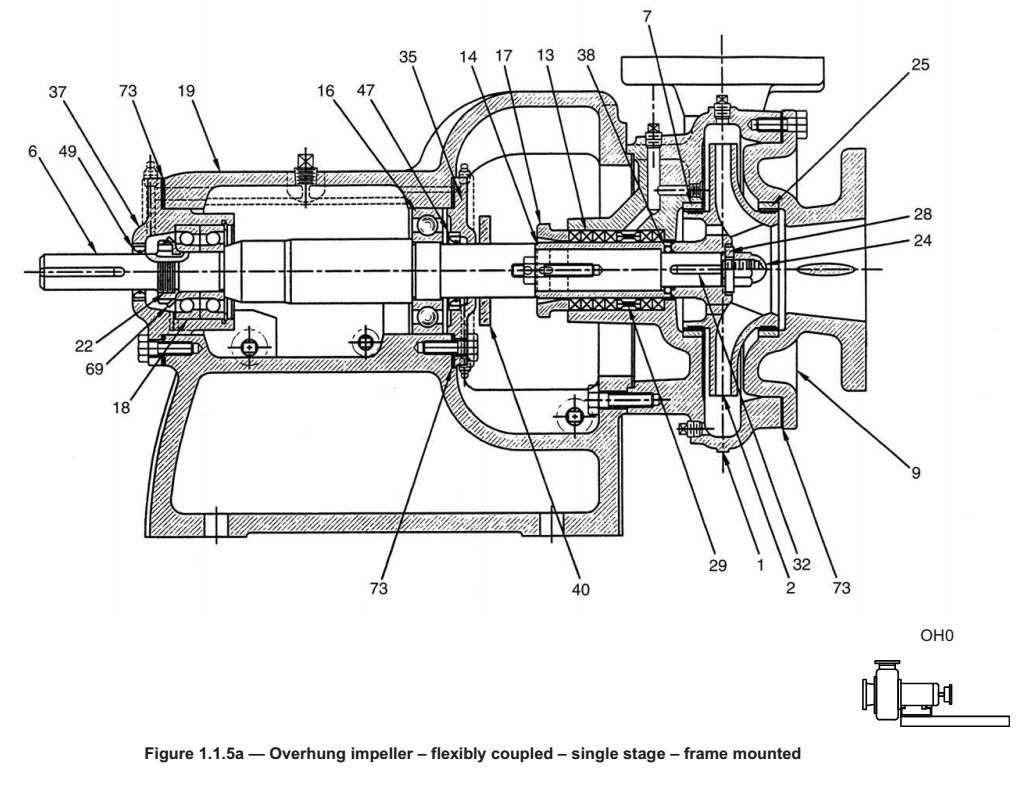

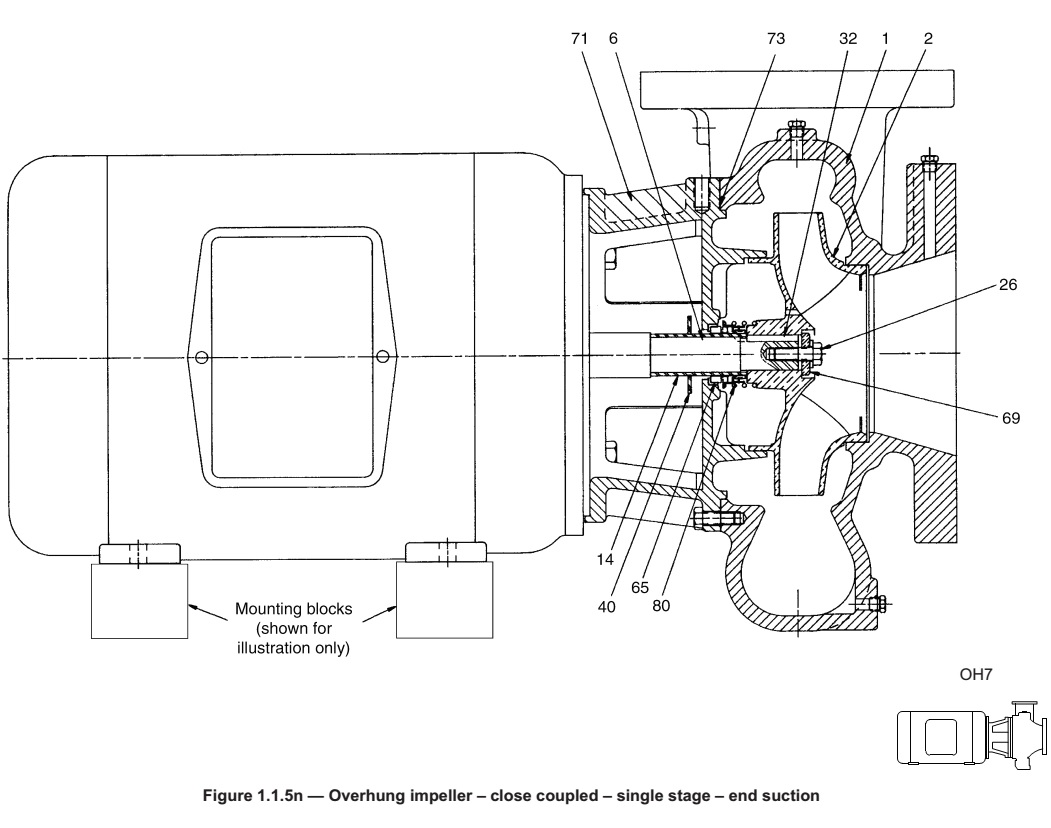

NPSH H1 ZD p amb - p vρ 1g where H1 inlet head Z D difference between NPSH datum plane and reference plane. An end-suction centrifugal pump can be long coupled separate coupling motor or close coupled where the motor is in the same unit with the pump often. Figure 1 on the following page is an illustration of a single end-suction centrifugal pump piping arrangement typi-.

Double suction pumps are mostly used for water supply and drainage in mines cities power stations and various water conservancy projects. Liquid enters through one side only. Self priming pump has the ability to evacuate air from the suction side at startup and then it operates similar to a normal pump.

This means that this pump will work correctly always and when the level difference between the end of the suction pipe and the pump suction port is less than or equal to 65 m. Single suction means as the name signifies one-sided suction of the impeller. A type of centrifugal pump that has a casing with the suction coming in one end and the discharge coming out the top.

End suction pump is a kind of water pump that is widely used in agriculture. End suction pumps are one of the most common types of centrifugal pumps. This pump can have higher axial thrust due to an imbalance of flow coming in only one side.

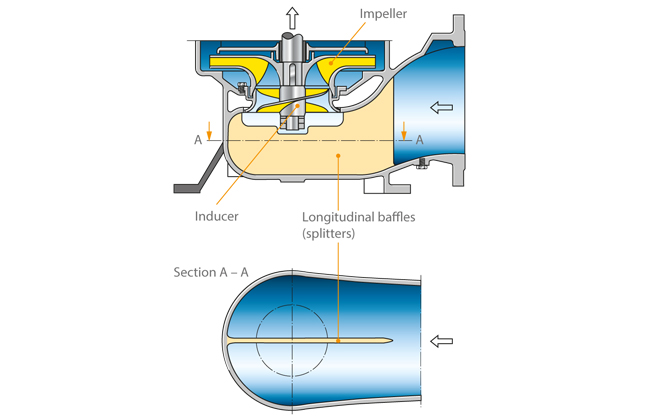

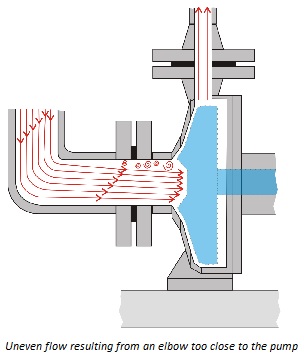

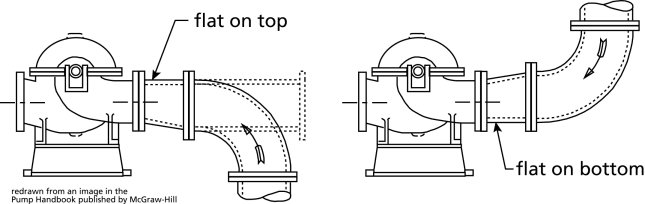

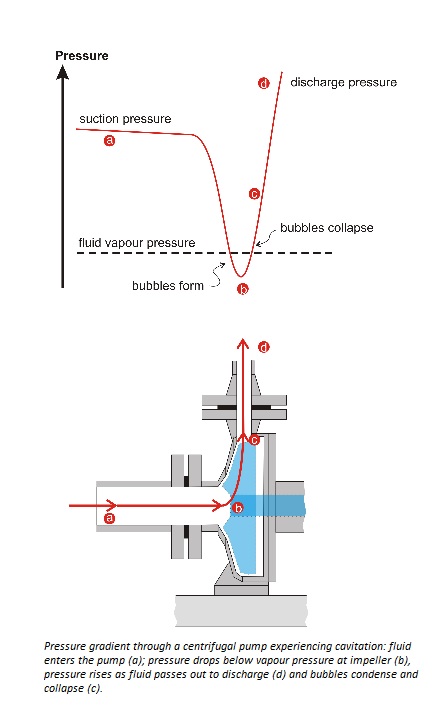

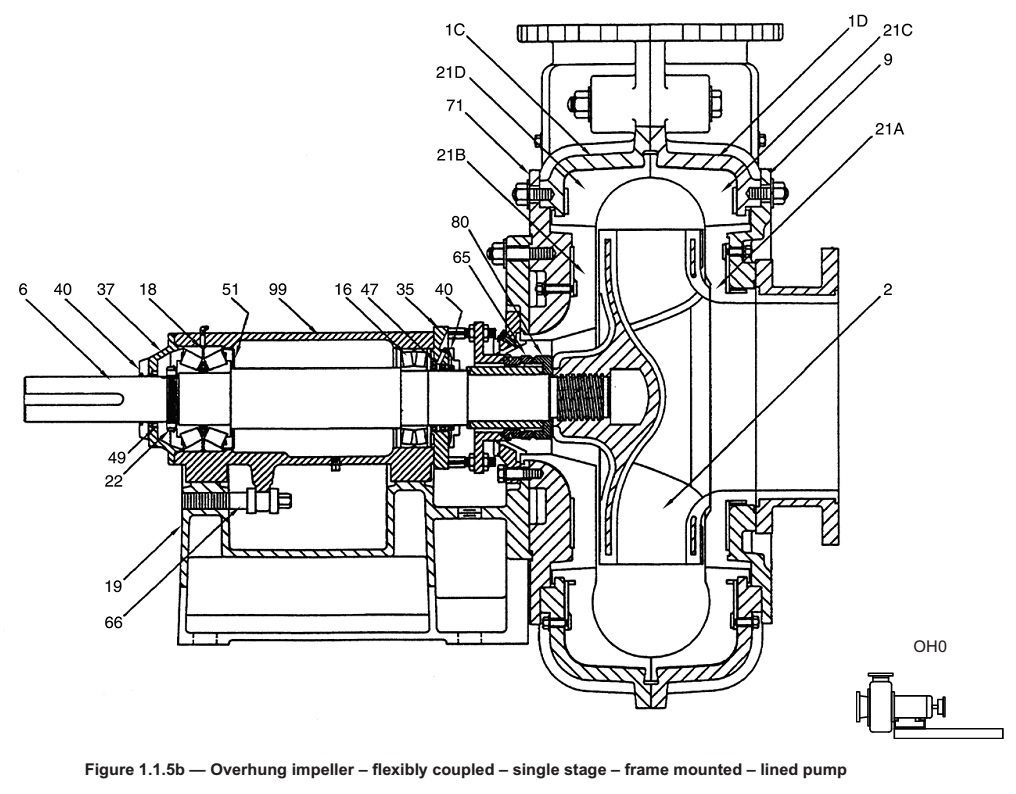

1314 Net positive suction head NPSH NPSH. End suction pumps generally have a. In double suction pumps if directly connected elbows can not be avoided they should be installed such that the elbows are in a plane perpendicular to the pump shaft.

Usually it is a single stage pump but some manufacturers make multi-stage versions. The pump is a centrifugal single stage single suction type. ANSI is an acronym that stands for American National Standards Institute.

Double Suction Between Bearing Split Case Pumps. End Suction Pumps SSF Overview Solutions Documentation Tools. An End Suction Pump is a type of Centrifugal Pump where the suction is axial and the discharge is at 90 degrees to the suction.

Flows to 70000 gpm 16000 m3h Heads to 230 ft TDH 70 m 12 to 30 Discharge 305 to 762 mm PROVEN PERFORMANCE WITH OVER 130 YEARS OF EXPERIENCE AND HIGH EFFICIENCIES PROVIDE CUSTOMIZED PUMPING SOLUTIONS FOR YOUR WATER AND. In this pump volume at each cycle of operation is constant. End suction pumps are the most common configuration for centrifugal pumps and the least expensive configuration in many cases.

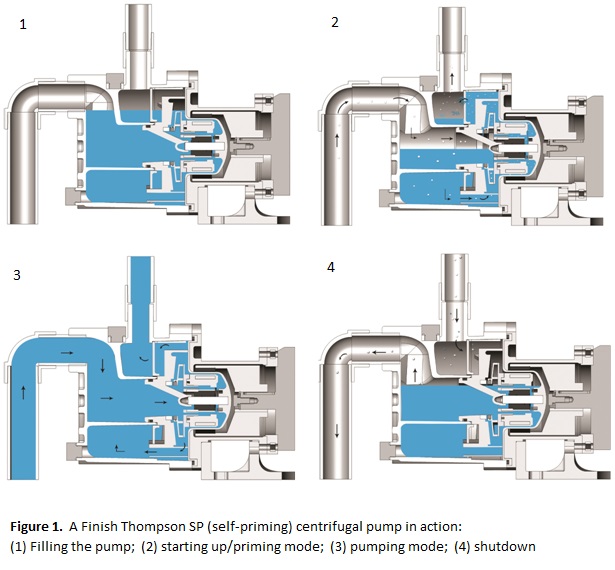

This blending allows the resulting mix to move readily through the pumps body on initial start-up removing the air and aiding product flow on the suction side of the pump. Self-priming centrifugal pumps overcome air binding by initially mixing any residual air in the pumps working mechanism with fluid during the priming process. The distance between the centerline of the pump and the surface of the fluid is measured in head feet this can.

End Suction Pump Meaning. When properly installed and when given reasonable care and maintenance centrifugal pumps should operate satisfactorily for a long period of time. It has a single-suction impeller.

A self priming pump is a specially designed end suction centrifugal pump with an external casing that always floods the inner pump or volute. Negative Suction Head means the pump is drawing liquid up from below its centerline. In this example hs 5 m ie.

When the flow required is very high a. An ANSI pump is one that conforms to ANSI Standard B731. For non-clog solids handling a range of horizontal vertical sump and submersible pumps have helped professional engineers solve pollution problems around the world.

This end suction pump choice is also a candidate for water service flow rates above about 3000 to 5000 gpm even though many pump users would probably be looking at Double Suction between bearing split case pumps in this flow range. They are almost always single stage pumps and one of the most cost effective types of centrifugal pumps. Available in a wide range of sizes construction materials and designs they can be used to pump a variety of fluids from.

Net Positive Suction Head is the absolute inlet total head above the head equivalent to the vapour pressure relative to the suction eye of the pump impeller. It takes some amount of fluid from one end that is the suction side and positively displaced in the discharge side. In this blog almost all of your questions regarding end suction pumps will be answered.

EXAMPLE 8 THEORETICAL SELECTION 2 STOREYS 1 STOREY hs5m hghshi5m6m11m hi6m. Double suction between bearing split case pumps see figure 3. End suction pumps are one of the most common types of centrifugal pumps.

Each type of pump has its own strengths and weaknesses.

4 3e Hh End Suction Split Case Centrifugal Slurry Pumps Warman Centrifugal Pump Irrigation Pumps

End Suction Pumps Intro To Pumps

M Slurry Pumps And Spare Parts To South Africa Warman Pumps Thermal Power Station

End Suction Pump Vs Split Case Pump Youtube

End Suction Pumps Intro To Pumps

Centrifugal Pump System Tips Do S And Dont S

Series E 1532 Close Coupled Foot Mounted End Suction Pumps Xylem Applied Water Systems United States

Centrifugal Pump Components Boilersinfo Centrifugal Pump Water Pump Motor Pumps

For Centrifugal Pumps End Suction Pumps Are One Of The Most Conventional Configurations Today There Is Found A Huge Industrial Pumps Centrifugal Pump Pumps

End Suction Pumps Intro To Pumps

Pentair Aurora 3800 Series Single Stage End Suction Centrifugal Pumps

Types Of Centrifugal Pumps Classification Working Principles Linquip

Ul Fire Pump Fire Fighting Pumps Pumps Fire Systems

Pump Suction Pipe Design Considerations

Pentair Aurora 3800 Series Single Stage End Suction Centrifugal Pumps

End Suction Pumps Intro To Pumps

Useful Information On Self Priming Pumps

End Suction Pump Centrifugal Durco Flowserve Chemical Process Ireland